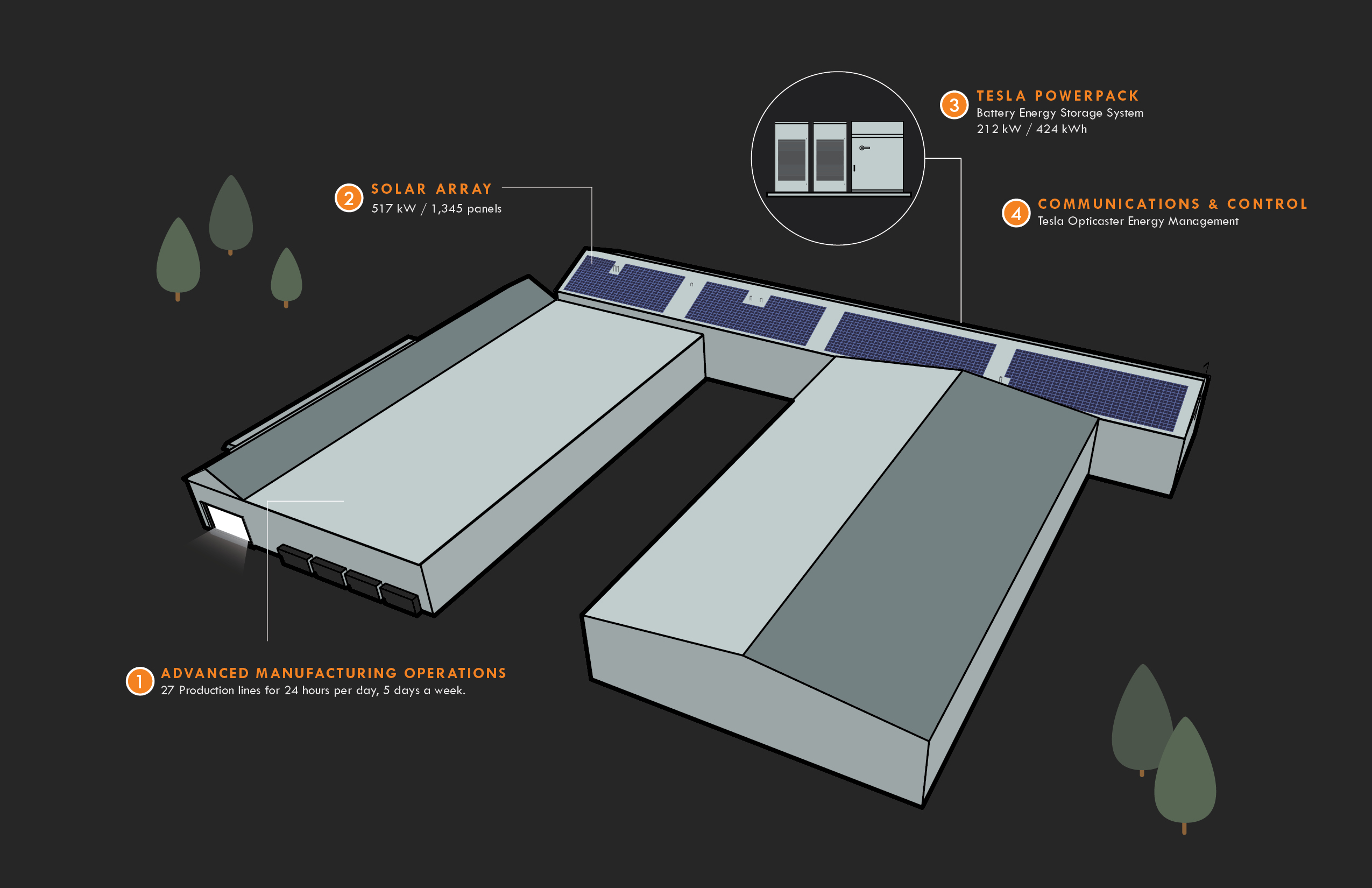

Agri-Industrial Plastics is molding a powerful future by leading as Iowa’s first advanced manufacturing company powered by solar energy and Tesla Powerpack.

Our Sustainability Policy

At Agri-Industrial Plastics Company we believe that success is about providing value to our customers, to our employees, and to our community for the long term. We believe that sustainability is about protecting the future of these same key stakeholders. We are therefore committed to:

- Full compliance of all applicable environmental laws

- Working to conserve our natural resources and eliminate waste in our manufacturing process and facility planning

- Operating as a good corporate citizen and neighbor

- Investing in solutions for the long term

Environmental Impact

We’re cutting our carbon emissions by 10,298 tons of CO2 with solar energy and Tesla batteries.

That’s equivalent to: